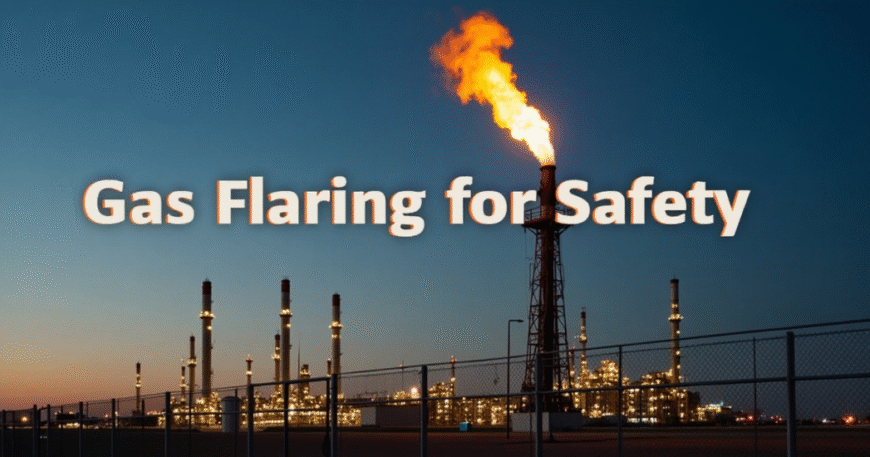

In industrial operations—particularly in sectors like oil & gas, petrochemicals, and refineries—safety is non-negotiable. One of the most critical components ensuring this safety is the Gas Flaring System. While often overlooked, flare systems play a vital role in protecting equipment, personnel, and the environment from potential hazards.

At The LUMINESCENCE, we specialize in the design and development of high-efficiency gas flaring systems that not only comply with safety regulations but also optimize performance and environmental responsibility.

🔥 What is a Gas Flaring System?

A Gas Flaring System is a controlled combustion device used to burn off excess or waste gases that cannot be processed or captured. This is common in oil & gas extraction, chemical manufacturing, and other industrial processes where volatile gases build up.

These systems are usually deployed during:

Emergency pressure relief

Startups and shutdowns

Routine maintenance

System upsets

By safely combusting hazardous gases, flare systems prevent dangerous pressure build-up, reduce fire and explosion risks, and minimize toxic emissions.

🛡️ The Role of Gas Flares in Industrial Safety

Here are several ways gas flaring systems contribute directly to industrial safety:

1. Pressure Relief and Explosion Prevention

During unexpected surges in pressure, gas flare systems act as a safety valve. They release the excess gas to a flare stack where it is safely burned off, preventing equipment failure or explosions.

2. Environmental Protection

Burning off gases through a flare is far safer than uncontrolled venting. Properly designed flare systems minimize the release of:

Methane (a potent greenhouse gas)

Volatile Organic Compounds (VOCs)

Toxic pollutants

This helps industries stay compliant with environmental regulations and avoid hefty penalties.

3. Emergency Response

In emergency scenarios like system malfunctions or power outages, flare systems provide a safe disposal route for flammable gases. This immediate response helps reduce downtime and protects personnel and assets.

4. Compliance with Safety Standards

Regulatory authorities across the globe, including CPCB, API, ASME, and OSHA, mandate the use of properly engineered flare systems. A compliant flare design reduces liability and ensures safe operations.

🛠️ Types of Gas Flaring Systems We Offer

At The LUMINESCENCE, we offer a wide range of flaring systems tailored to specific operational needs:

Self-Supported Flares

Guy Rope Supported Flares

Derrick Supported Flares

Demountable Flares

Sonic & Subsonic Flares

Enclosed Ground Flares

Flare Gas Recovery Systems (FGRS)

Each system is engineered using advanced software like FLARESIM, PV-Elite, and CFD, ensuring optimum combustion, efficiency, and environmental compliance.

👷 Why Trust The LUMINESCENCE?

With over 15 years of engineering experience and a passionate team of experts, we deliver solutions that are:

Custom-designed for each facility

Tested for maximum safety and performance

Backed by full installation and maintenance support

We don’t just supply products—we build long-term safety solutions for your business.

✅ Final Thoughts

In an age where industrial risk management is more crucial than ever, investing in a reliable gas flaring system is not a choice—it’s a necessity. Whether it’s about safeguarding human lives or ensuring environmental compliance, flaring systems are a silent guardian behind the scenes of every industrial plant.

Looking to upgrade or install a high-performance gas flaring system?

Get in touch with The LUMINESCENCE — where safety meets innovation.